Look for in a Rigid-Flex PCB Manufacturer

The demand for rigid-flex PCBs is on the rise due to their utility in complex and compact electronics. Choosing the right manufacturer is crucial to ensure quality and efficiency in your electronic devices. The right manufacturer will be able to offer a range of benefits and will have the capacity to produce high-quality products at competitive prices. What to Look for in a Rigid-Flex PCB Manufacturer

In the process of selecting a flex rigid pcb manufacturer, you should consider their experience and reputation in the industry. You should also check their technical capabilities and facilities. Additionally, it is important to evaluate the manufacturer’s prototyping and production capabilities. Finally, you should examine their delivery timeframes and logistics. A reputable manufacturer will offer transparency and collaboration throughout the process, ensuring quality results and a smooth manufacturing experience.

A reliable rigid-flex PCB manufacturer will be able to meet your design requirements and provide personalized customer support. They should also have a good understanding of rigid-flex design rules and can offer a wide variety of layout options. In addition, they should be able to offer flexible production and turnaround times.

What to Look for in a Rigid-Flex PCB Manufacturer

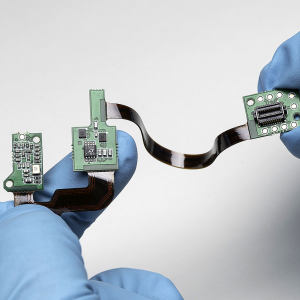

Rigid-flex PCBs are a combination of rigid and flexible printed circuit boards. They are made using copper clad laminates and can be used in a variety of applications. These include aerospace, automotive, and medical devices. The use of rigid-flex PCBs can help reduce space, weight, and cost of electronic devices. Moreover, these circuits can accommodate different sizes and shapes of components.

The construction of a rigid-flex PCB involves etching the copper, forming the holes, and mounting the components. In addition, the flex circuits are coated with an adhesive. The layers are then bonded together using acrylic or epoxy adhesives. They are also insulated by a layer of polyimide. Bondply is often used to encapsulate the etched details in heavy copper multi-layered constructions of flex/rigid-flex boards.

Another benefit of a rigid-flex PCB is the ability to dissipate heat. As current flows through the PCB, it produces heat, which is dissipated through the circuit board’s thermal management system. Hence, it is important to consider the thermal performance of the rigid-flex PCB in your design process.

Rigid flex PCBs allow for easier testing and simplified assembly processes. They are also more durable and reliable than rigid PCBs. In addition, they can withstand harsh environments and are suitable for high-density applications.

When selecting a rigid-flex PCB manufacturer, it is critical to choose one with a quality control process. This includes inspection methods and testing equipment. In addition, the manufacturer should be ISO and UL certified. This will ensure that the product meets industry standards.

It is also a good idea to ask for references from the manufacturer’s previous customers. These references can provide valuable insights into the manufacturer’s level of expertise and reliability. You should also ask about the manufacturer’s turnaround times and their customer service. If possible, you should visit the manufacturer’s facilities and speak with their engineers to get a better idea of the quality of their work.