Flexible PCB Boards

If you’re looking to add a flexible strain sensor to your project, the best place to start is with a flexible circuit board (FCB). These are a type of printed circuit board that incorporates conductive copper layers and a layer of dielectric material. They’re ideal for a wide variety of applications, as they can bend and twist to adapt to the shape of your product while remaining fully functional. They’re also easy to work with, as they’re often designed using standard PCB fabrication techniques.

In addition to being more versatile than rigid PCBs, flexible circuit boards are often lighter and have a thinner profile. This can reduce manufacturing costs by allowing you to use a smaller amount of space in your application. It can also save space in the assembly area, making it easier to fit in components and wires.

Another benefit of using FCBs is their ability to withstand high-stress conditions. This is because they’re designed with more flex than rigid PCBs, which make them better at absorbing shock and vibration. They’re also able to withstand more bending than standard flexible pcb board, which makes them perfect for use in mobile phones and other electronic devices with a lot of movement.

Flexible PCB Boards for Flexible Strain Sensors

The conductive materials used in flex circuits are a bit different than those used on rigid PCBs. They can be made from metals like aluminum or nickel, or from polymers like phenolic and polyimide. These are usually coated with a protective solder mask and silk screen. In addition, some of them are treated with tin or soft gold to increase corrosion resistance and durability.

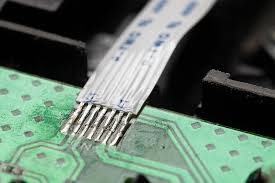

A common design for a flex circuit is the single-sided flex PCB. This is one of the most common types, and it has a conductive copper layer on one side and a protective silk screen on the other. It can be drilled to create the necessary holes for components, which is an important step in the etching process.

For the more complex designs, a dual-layer flex PCB can be used. This type of circuit board has two copper layers that are separated by an in-between layer of polyimide. This allows for twice the density of electrical connections than a single-layer design. It can also be coated with an electroless nickel immersion gold (ENIG) finish, which increases corrosion resistance and extends its lifespan.

A rigid-flex PCB is a hybrid design that connects rigid and flexible areas of the board. The rigid sections are made of materials similar to standard PCBs, including fiberglass and metal. The flex section, however, uses a thicker, more durable layer of polyimide. Some manufacturers also use a layer of prereg fiberglass as the middle substrate layer. Depending on the requirements of your application, you may choose to use standard copper or upgraded rolled-annealed copper. The latter has a higher tolerance to humidity and tears than standard copper. The CAD features and automated drawing tools in Altium Designer help you to select the correct materials for your flex circuit.